PRODUCTS

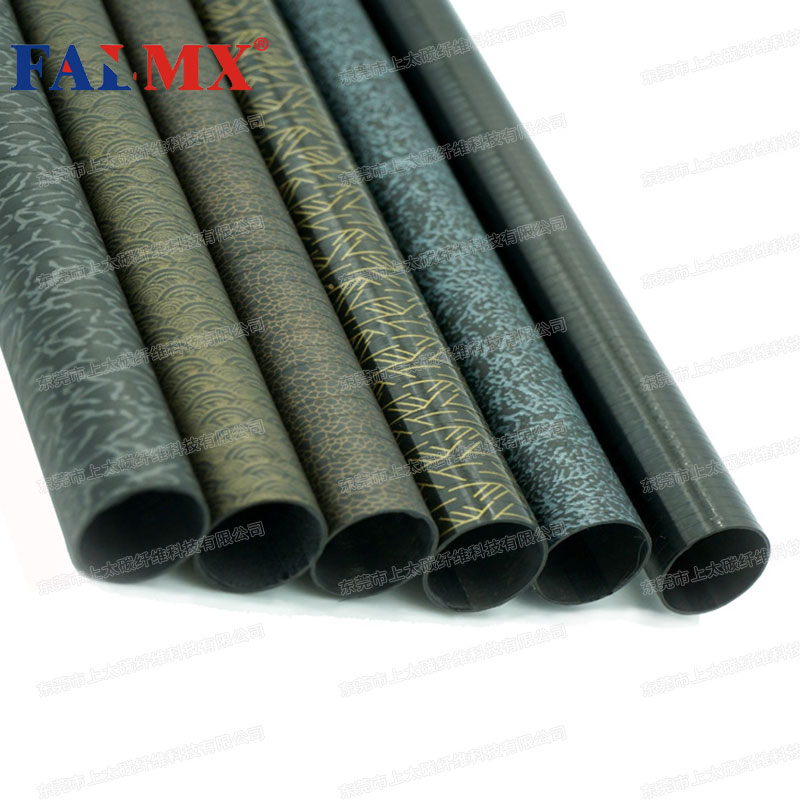

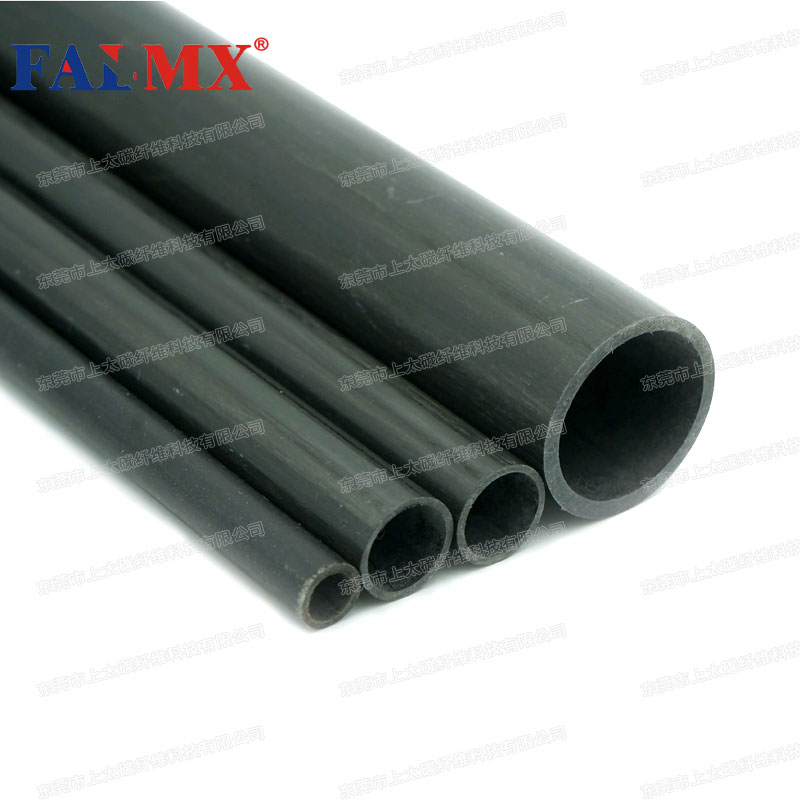

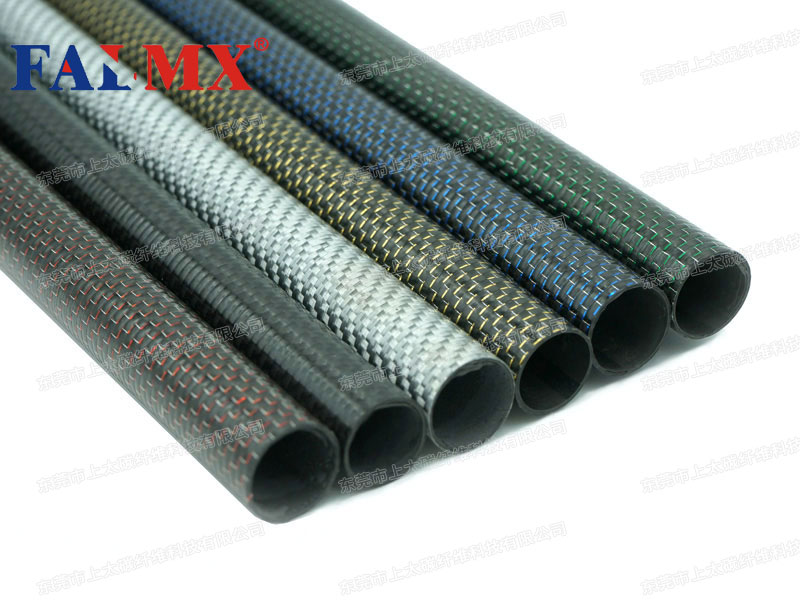

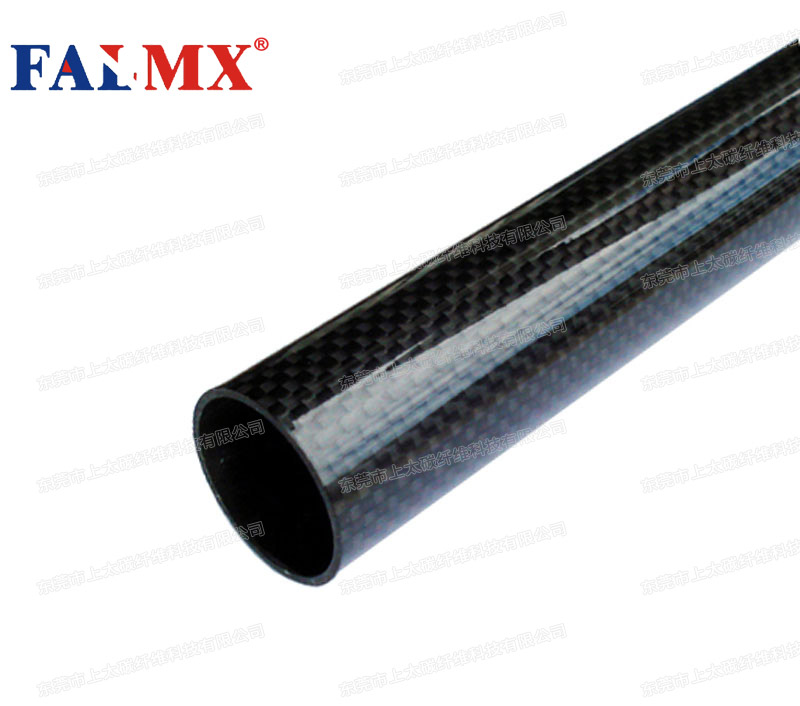

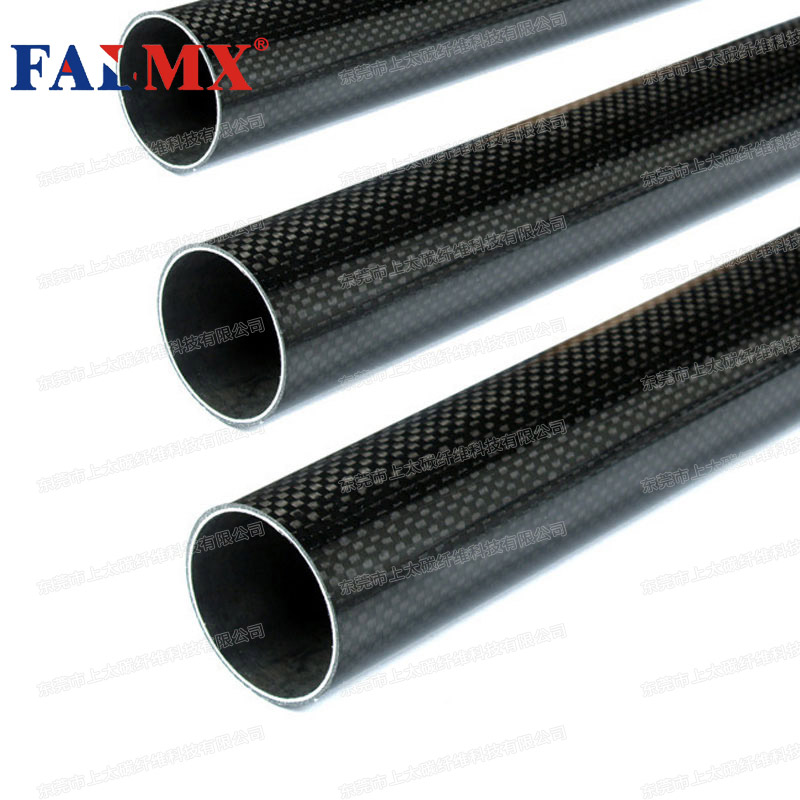

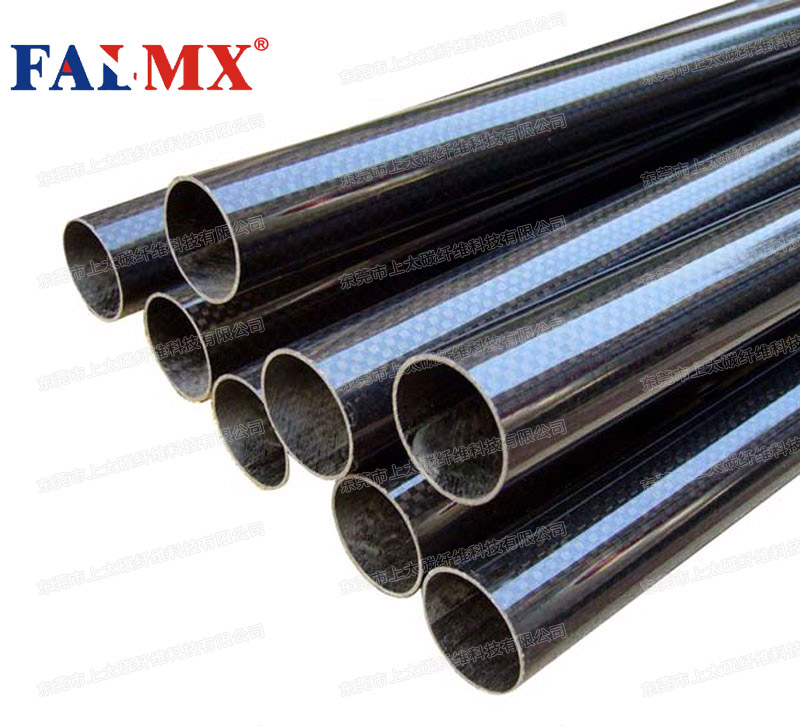

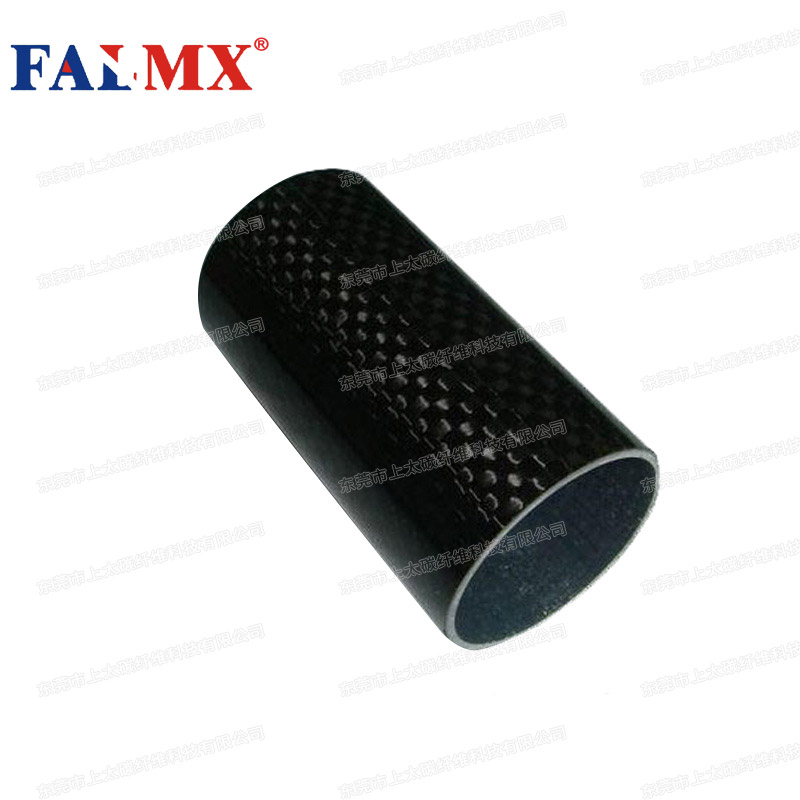

Carbon fiber 3K coiled tube

Brand/Model: FALMX/ST-CCT001

Material: Carbon fiber

Place of Origin: Dongguan, Guangdong, China

Wall thickness: 0-500mm

Diameter: 0-500mm

Production process: roll forming process

Product description:

Technical features

1. High strength and high efficiency:

The tensile strength is more than several times that of ordinary steel, the modulus of elasticity is better than that of steel, and it has excellent creep resistance, corrosion resistance and shock resistance.

2. Light weight and good flexibility:

The carbon fiber has high strength, the quality is only 1/4 of rigidity, and it has high toughness.

3. Good durability and corrosion resistance:

It is resistant to acid, alkali, salt and atmospheric corrosion and does not require regular maintenance.

Product details

Application field

--Remote control model cars, boats, airplanes and other accessories;

--Surface decoration of glasses, leather goods, penholders, notebooks, jewelry, furniture, etc.;

--High-end sports equipment;

--Mobile phones, laptops;

--Sports equipment accessories, medical equipment, auto parts, electronics, hardware, jewelry and other products;

--Fishing gear, fishing line, wheel brakes, rocker arms, etc.

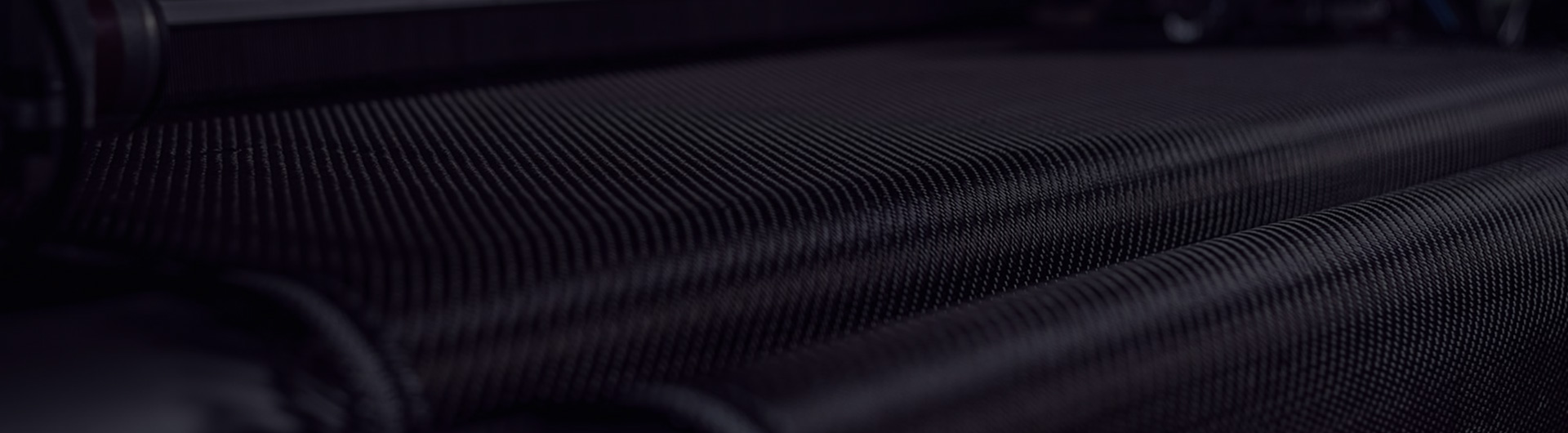

Carbon fiber rolling process

There are four basic steps in the process:

1) Prefabrication stage: Determine the length of the prepreg according to the thickness of the wall tube, carefully clean the core mold, apply a release agent, and then adjust the position of the core mold and prepreg to prepare the roll system.

2) Coiling stage: After the coiling machine is running, the material is fed at a constant speed, and the prepreg is evenly rolled onto the core mold through the force of the pressure plate. Then place the rolled carbon fiber tube together with the core mold on the rolling press to further compact the prepreg and wrap it with a layer of film.

3) Curing stage: Take the compacted carbon fiber tube out of the tube press and send it to the curing oven for curing. After the tube is cured, remove the core model to get the initial shape of the Carbon fiber tube.

4) Processing stage: Place the Carbon fiber tube with the surface coating removed in a grinder to polish the surface to make it smooth and flat, and then spray paint. After this step, a second time is required Fine grinding and finishing according to the required size of the product until it reaches the final requirements of the pipe.

Recommended list

Want to learn more about the company's products and information?

Enter your email address

Contact Us

Tel: +86-769-8298 7125

Fax: +86-769-8298 7126

Add.: Xiegang Town, Dongguan City, Guangdong Province, China

Follow Us

Copyright© 2021 Dongguan City Shangtai Carbon Fiber Technology Co., Ltd. Powered by www.300.cn

Copyright© 2021 Dongguan City Shangtai Carbon Fiber Technology Co., Ltd.

Language

Language